Quick Action Spindle & Shaft Locking Clamps

Shaft clamps for quick and easy locking. Available in manual or pneumatic. Simple operation without the use of tools.

Features

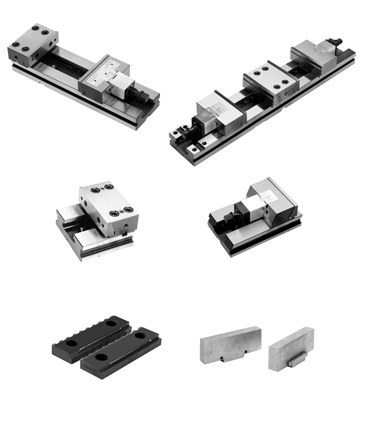

Manual Version

More Efficient Than Conventional Method-

As the handle is turned down, the locking block is pushed toward the shaft for clamping. When the handle is released, the flat spring allows the locking block to return back to the original position.

Feature 1. Simple Handle Operation Without Any Tools

Simple vertical handle motion is perfect for applications where position adjustments are often made.

For locking, the handle is moved down as directed by the arrow mark on the side. For releasing, the handle is moved up.

Set screws and adjustable handles are NOT needed. No tools are needed for handle operation!

Feature 2. Compact-Designed & Space-Saving

Imao Method

No space is needed for the handle to swing.

Conventional Method

Some space is necessary for the handle to swing.

Compact size for installation even in small space. Proper Shaft Diameter(mm) : 10 12 14 15 16 20.

Feature 3. Different Mounting Capability

Both front and back faces can be used for mounting. The tapped holes on the 2 sides allows for versatile mounting.

Application Examples

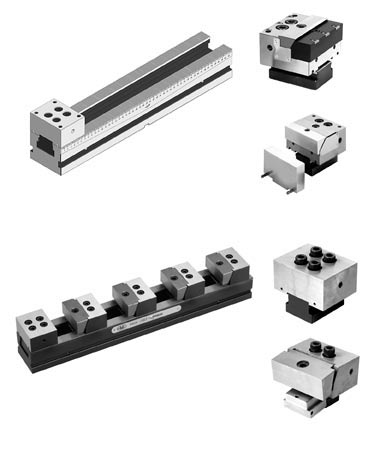

Pneumatic Version

Unclamping by air pressure. Clamping by spring pressure.

Supplying air compresses the spring to get the shaft unlocked. Releasing the air locks the shaft.

Feature 1. Simultaneous Multi-Clamping Capability

Connecting air plumbing to multiple quick shaft-locking clamps installed allows clamping/unclamping in one operation. Perfect for use on machines where many clamping or unclamping cycles are run, or for multi-clamping applications.

Feature 2. Remote-Operation Capability

With air supply, remote operation can be done or installation is possible at places out of reach. Can be also installed at invisible places like the backside of machines, for maintenance of machines' appearance.

Feature 3. Positive Clamping

The mechanism of spring-pressure clamping and air-pressure unclamping prevents any decrease of shaft-locking force. With clamping automization, any operator can do uniform clamping.

Feature 4. Space-Saving

No need for a larger installation space than the body size (no handle-operating space needed).

Features

Positive Locking

Spring clamping and pneumatic unclamping mechanism prevents the decrease of clamping force by air leakage.

Compact or Heavy Duty

Choose the clamp type that meets your required load. Shaft Diameter (mm) : 10, 12, 16, 20.

Remote / Multiple Operation

Multiple shafts can be clamped at a time from a distance. Installation is possible at places out of reach.

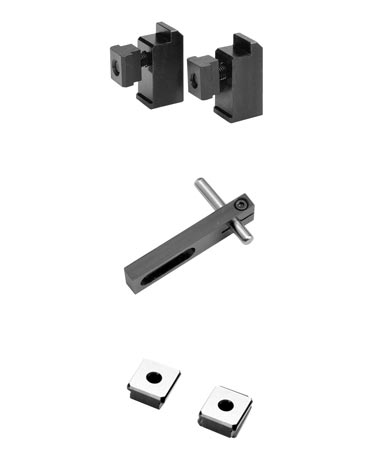

Features

Sliding Shaft Locking

Lock for position adjustment.

Horizontal lock with pneumatic cylinder.

Vertical lock for elevator table.

Spindle Locking

Lock for threaded spindle.

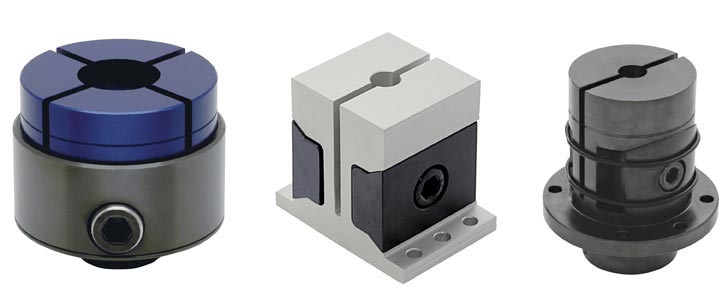

Conventional Method

- Over tightening

- Under tightening

- Interference of handle

IMAO Method

- Reliable locking of spindles with one-touch action!

- Just a quarter-turn of the knob!

Spindle Lock Features

Easy Operation

Just turn the knob one quarter-turn.

Levelling of Operation

Click of the knob indicates the spindle is locked. Locking force is unified no matter who operates.

Highly Visible

Easy-to-read lock/unlock position.

Application Example

Adjustment of conveyer guide.

Adjustment of tension roller angle.

Adjustment of microscope height.

Breaking test equipment.

Adjustment of caser guide.

Combination with Mechanical Linear Actuator.

Line up

View Cart {{shoppingcart.totalQuantityDisplay}} Item(s)

View Cart {{shoppingcart.totalQuantityDisplay}} Item(s)

View Cart {{shoppingcart.totalQuantityDisplay}} Item(s)

View Cart {{shoppingcart.totalQuantityDisplay}} Item(s)